Cordis Manufacturing Solutions

PRECISION MANUFACTURING

Expertise, Quality, Delivered at Scale

Who We Are: Pioneers of Innovation & Performance

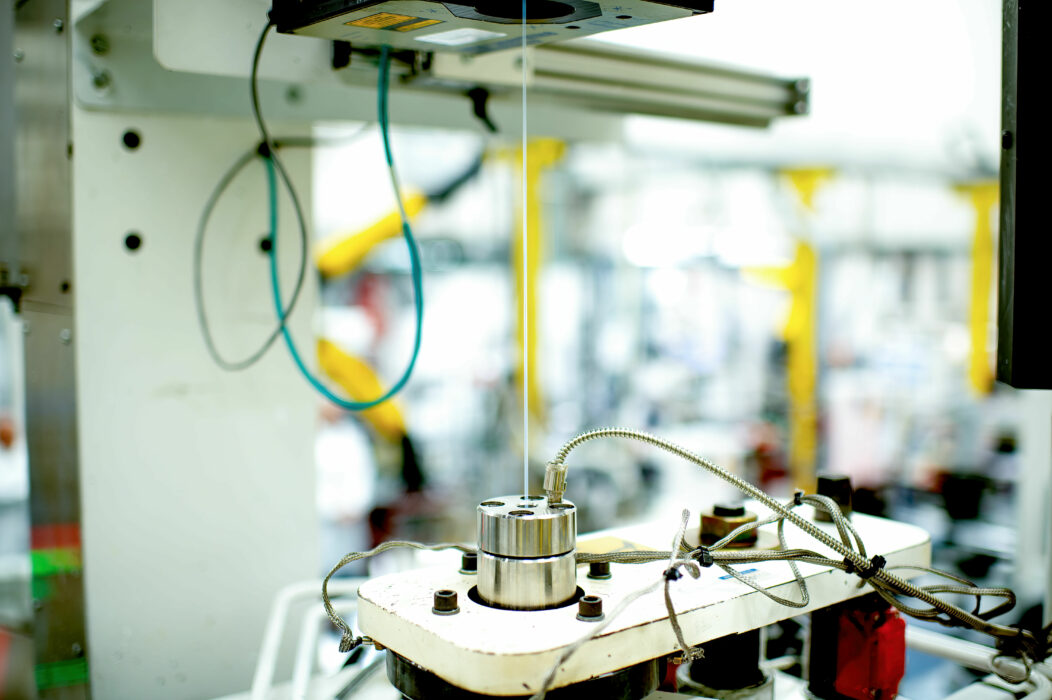

At Cordis Manufacturing Solutions, we specialize in precision-engineered PTFE, FEP, and PEEK components designed for next-generation interventional devices. With over 60 years of medical expertise, our team understands the critical role these components play in device performance and patient outcomes. Unlike other manufacturers who serve multiple industries, we are exclusively focused on medical-grade components—ensuring superior quality, compliance, and consistency in every product.

Our Capabilities: Precision Manufacturing & Customization

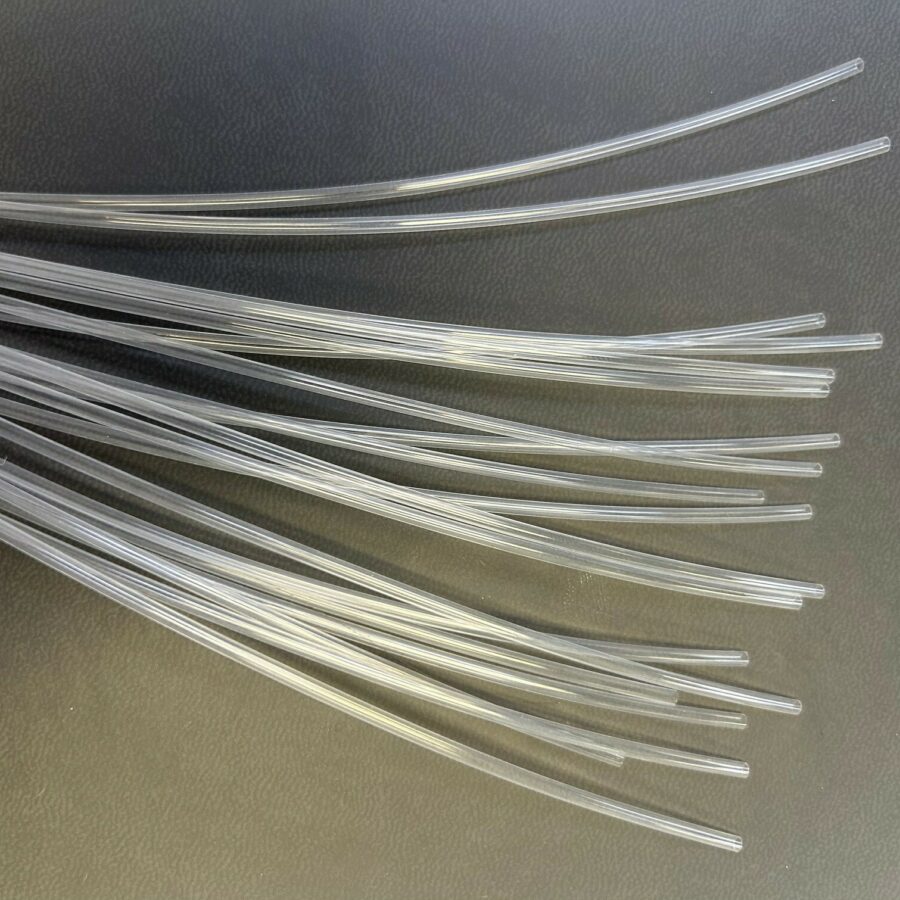

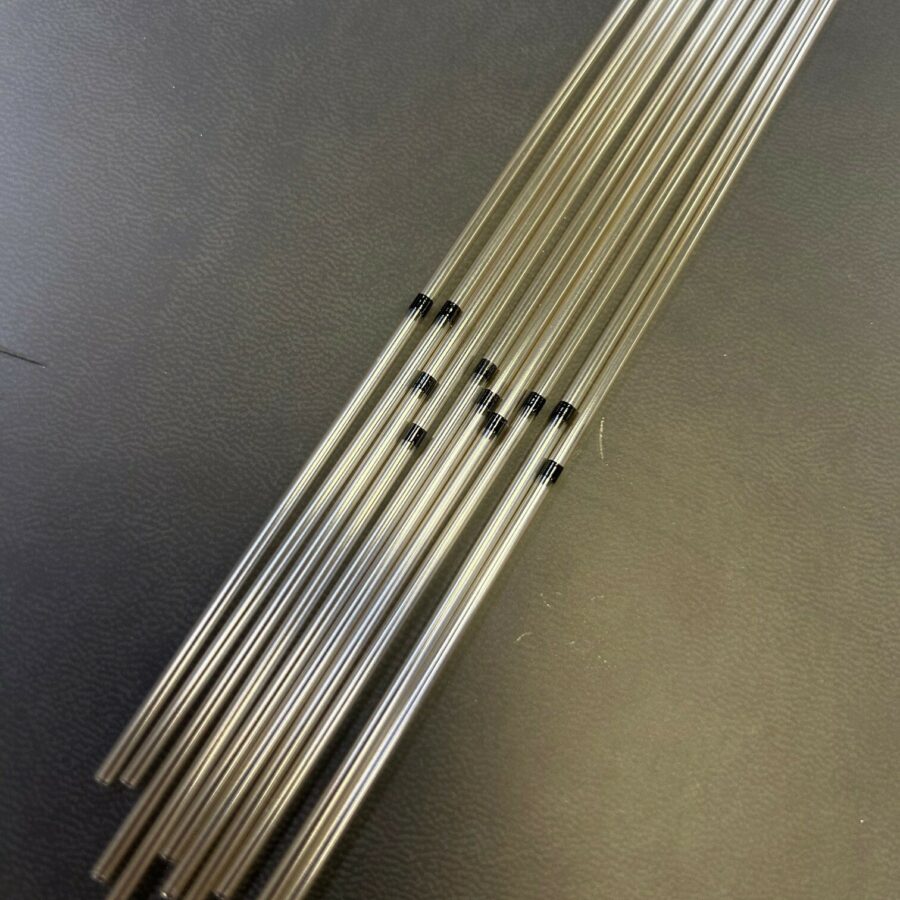

Cordis Manufacturing Solutions delivers customized, high-performance medical components through proprietary manufacturing processes. From PTFE liners with ultra-thin walls to FEP heat-shrink tubing engineered for catheter reinforcement, our products meet the most demanding specifications. We offer inline chemical etching for superior bonding, tightly controlled tolerances, and high-yield processes that ensure cost-effective, repeatable quality. Every component is manufactured in our ISO 13485-certified, FDA-registered facility in the U.S., ensuring global regulatory compliance.

Our Materials: Science-Driven Performance

The right material choice is critical for medical device performance. Our expertise in PTFE, FEP, and PEEK allows us to recommend optimal solutions for catheter liners, shrink tubing, and medical device components.

Our Scalable Supply & Prototyping: Designed To Meet Your Needs

At Cordis Manufacturing Solutions, we support your full development lifecycle with both custom manufacturing and small-batch components designed to meet your unique demands for interventional medical devices.

Our custom manufacturing capabilities are built on decades of catheter and component expertise. We deliver precision PTFE, FEP, and PEEK components tailored to your needs — including tight ID/OD tolerances, ultra-thin walls, etched surfaces, and complex geometries.

Through rapid prototyping services, we support fast design iteration and low-volume validation with short lead times and tooling flexibility. Our engineering-first approach ensures you get to functional prototypes faster, with the same quality controls used in scaled production.

To make sourcing even easier, Cordis components are available in small-batch quantities through our distribution partner Chamfr — giving startups, R&D teams, and pilot projects on-demand access to proven polymeric components.

Customer Service and Inquiries

Please email us your questions or call us at 800.327.7714.